Photovoltaic Silicon Wafer Cutting Wire, also known as tungsten diamond wire, is specifically designed for precision cutting of silicon wafers in the solar energy industry. This wire features exceptional strength and precision, making it ideal for high-volume photovoltaic production processes.

Key Features:

1. Fine Wire Diameter: Tungsten diamond wire is available in diameters ranging from 26μm to 35μm, offering greater precision and material savings during the cutting process.

2. High Tensile Strength: Tungsten wire offers higher tensile strength compared to carbon steel diamond wire, resulting in less wire breakage and improved cutting performance.

3. Extended Service Life: Tungsten diamond wire can last up to ten times longer than traditional carbon steel diamond wire, reducing downtime and improving operational efficiency.

4. Low Breakage Rate: With superior tensile strength, tungsten wire experiences fewer breakages, resulting in a smoother cutting process and less wastage.

Applications:

1. Photovoltaic Industry: Mainly used in the production of silicon wafers for solar cells, ensuring high precision and low material loss during cutting.

2. Semiconductor Industry: Tungsten cutting wire is also used in the semiconductor industry for cutting wafers, where precision and minimal wire breakage are essential.

Advantages over Carbon Steel Wire:

1. Longer Lifespan: The enhanced durability and strength lead to fewer replacements and higher productivity.

2. Smaller Diameter: The finer wire allows for more precise cuts, minimizing material waste and improving product yield.

Specifications:

1. Length

2. Tensile Strength

3. Ovality

4. Wire Diameter

5. Coil Diameter

6. Defect Points

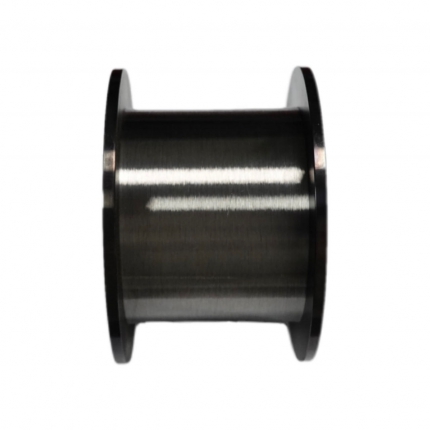

7. Spooling

Additional Considerations:

1. Surface Finish

2. Flexibility

3. Torsional Strength

The data may vary based on wire diameter. For specific requirements, please contact us.